Screens play a crucial role in our daily interaction with technology, and they can damage eyesight or cause eye fatigue, among other problems. So that this does not happen while you are enjoying reading your favorite eBook, you should choose screens with this technology that we are telling you about today. Among the various display technologies available, e-Ink screens, or electronic ink, have gained popularity due to their unique set of features, enhancing the reader's experience and making it as close to reading on paper as possible.

But… do you really know what they are?

What is e-Ink or ePaper?

It can be called by various names, such as electronic paper or ePaper, or also known as electronic ink or e-Ink. Regardless of what you call it, it is a type of display screen panel that mimics the appearance of ordinary ink on paper. Unlike conventional flat displays that emit light, an e-paper display reflects ambient light, just like paper. This can make them more comfortable to read and provide a wider viewing angle than most light-emitting displays. The contrast ratio on available electronic displays approaches that of a newspaper, and newly developed displays are slightly better. An ideal e-paper screen can be read in direct sunlight without the image appearing to fade, as happens with many other devices such as tablets, smartphones, computers, etc.

Many e-paper technologies keep text and static images indefinitely without electricity. This also makes them ideal for mobile devices that depend on a battery, so you can extend the autonomy for days or weeks, depending on the total consumption of the device's hardware.

How e-Ink or ePaper works

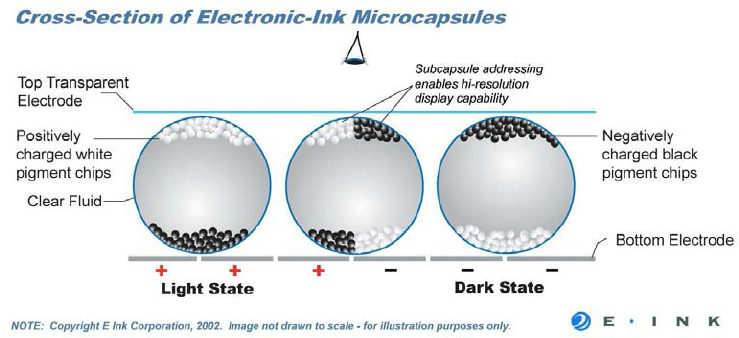

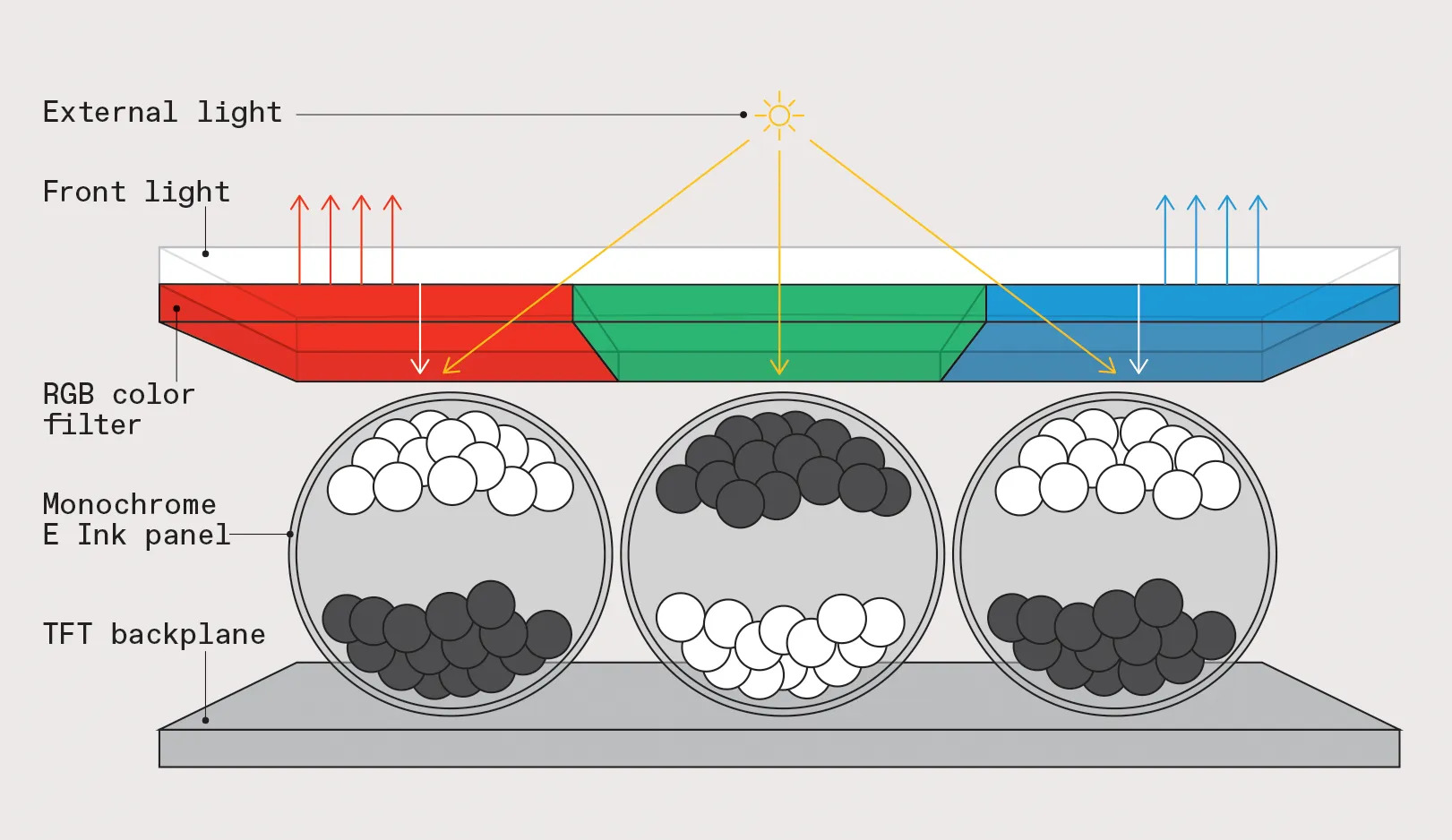

It cannot be generalized about the way of working of electronic ink screens, or e-Ink, since there are many technologies and each one works differently, as we will see later in the types section. But for example, Through electrophoresis when an electric field is applied to the microcapsule, the charged particles move towards the oppositely charged electrode. For example, if the bottom electrode is positive, the black particles will move down and the white particles will move up.

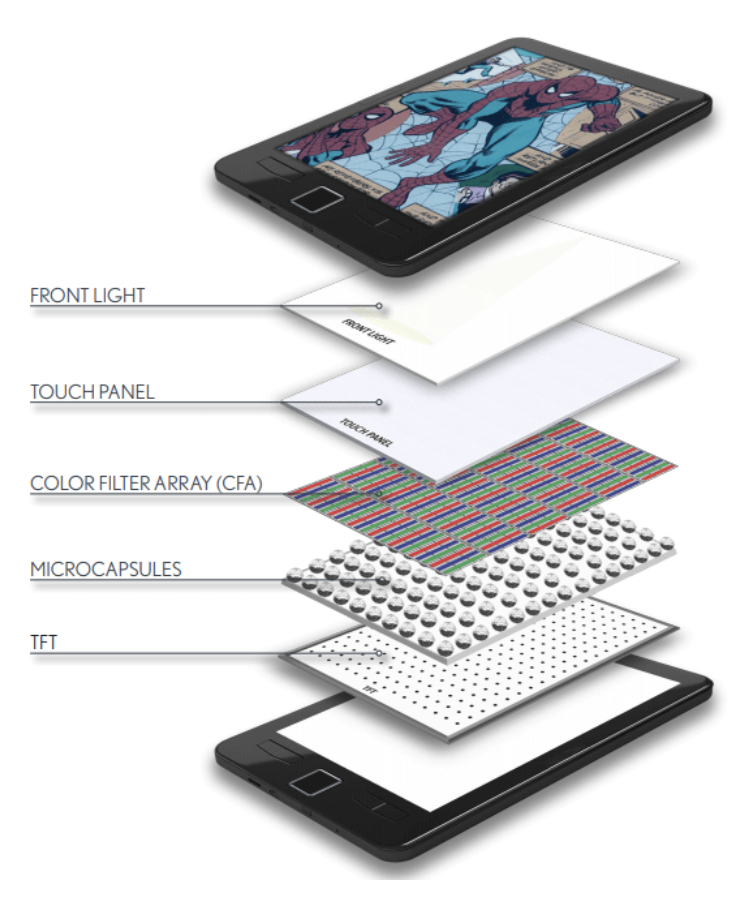

- Microcapsules: They are composed of millions of microcapsules, each of which is approximately the same width as a human hair. Each microcapsule contains charged particles suspended in a clear fluid. These capsules are distributed throughout the entire panel or screen. Inside each microcapsule there are white particles that carry a positive charge and black particles that carry a negative charge. Simple operation, they are polarized according to electrical charge to display text and image, in black and white. In this way you can see a black or white dot or pixel...

One of the key features of e-Ink displays is their bistability. This means that once an image has been formed, no energy is needed to maintain it. The image will remain on the screen even when the power supply is removed. Hence its low consumption compared to conventional screens.

Nowadays, technology has advanced, so there are also color screens, more advanced, and that can show a multitude of colors, to show images from books, comics, etc.

A Little History

Although it may seem quite recent, the truth is that the history of these screens goes back a few decades, specifically to the 1970s, when Nick Sheridon, from Xerox Palo Alto Research Center, developed the first electronic paper called Gyricon. This innovative material consisted of polyethylene spheres that could rotate freely, displaying a white or black side depending on the polarity of the applied voltage, thus creating the appearance of an electrically controlled black or white pixel.

Despite this advance, the idea of a low-power screen that imitated paper did not materialize until decades later. Was physicist Joseph Jacobson, while a postdoctoral student at Stanford University, who imagined a multi-page book whose contents could be changed with the push of a button and that required little power to operate.

Jacobson was recruited by Neil Gershenfeld to the MIT Media Lab in 1995. There, Jacobson recruited two MIT undergraduate students, Barrett Comiskey and JD Albert, to create the necessary display technology. to make your vision a reality.

The initial focus was to create small spheres that were half white and half black, like Xerox's Gyricon. However, this approach proved to be a considerable challenge. During his experiments, Albert accidentally created some completely white spheres. Comiskey experimented with loading and encapsulating these white particles into microcapsules mixed with a dark dye. The result was a system of microcapsules that could be applied to a surface and charged independently to create black and white images.

En 1996, MIT filed the first patent for microencapsulated electrophoretic display. The advantage of the microencapsulated electrophoretic display and its potential to meet the practical requirements of electronic paper was seen as a major breakthrough, with a view to its use in reading devices, among others. However, the technology was still primitive at this time, and color displays of this type did not exist.

In 1997, Albert, Comiskey and Jacobson, along with Russ Wilcox and Jerome Rubin, founded the E-Ink Corporation, two months before Albert and Comiskey's graduation. Since then, e-Ink technology has continued to evolve, finding applications in a variety of devices and transforming our interaction with digital technology…

This company Taiwanese company that manufactures and distributes screens electrophoresis, benefited from several movements to become dominant in the sector. For example, in 2005, Philips sold the e-paper business to Prime View International (PVI), a manufacturer based in Hsinchu, Taiwan. In 2008, E Ink Corp. announced an initial agreement to be purchased by PVI for $215 million, an amount that eventually reached $450 million after negotiations. E-Ink was officially acquired on December 24, 2009. The purchase by PVI expanded the production scale for the E-Ink e-paper display. PVI renamed itself E Ink Holdings Inc. after the purchase. In December 2012, it acquired SiPix, a rival electrophoretic display company, to strengthen its leadership today.

e-Ink Screen Applications

With the advancement and maturation of this technology, many companies have begun to develop or acquire screens of this type from their suppliers to use them in a multitude of applications, although the best known are ereaders, the truth is that there have been attempts and applications in other sectors:

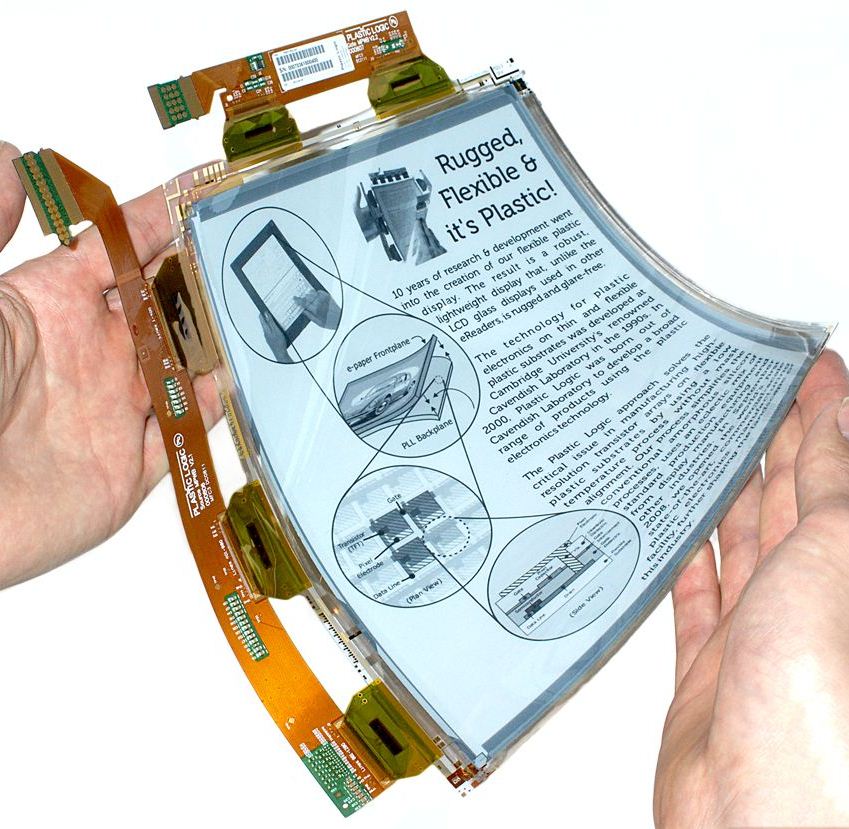

- Flexible screens: since this technology adapts well to rigid panels and also those that can be bent. For example, it can be used for some flexible mobile devices or wearables, such as the low-cost Motorola F3, Samsung Alias 2, YotaPhone, Hisense A5c, which use an e-Ink screen instead of LCD, or the Seiko's Spectrum SVRD001, the Sharp Pebble, etc.

- ereaders: as we have already mentioned, like the ones we have on this page, from various brands, Sony, Kindle, Kobo, Onyx, etc. In addition, there are already both conventional screens and touch screens, as well as color screens or screens sensitive to electronic pens.

- Laptops and PC monitors: Although it is not common, there have been some special models, such as the Lenovo ThinkBook Plus, with an e-Paper screen. We also see many Android tablets that use this type of screen, to make 2-in-1 devices or hybrids between an eReader and a tablet.

- electronic newspapers: Flemish daily De Tijd also distributed an electronic version of its paper newspaper in a limited version, using a preliminary version of the iRex iLiad. Some other examples would come later.

- Smart Cards and peripherals- Some smart cards can also use this type of e-ink displays for low consumption, such as those manufactured by Nagra ID and developments by Innovative Card Technologies and nCryptone. They were also used for some other peripherals, such as USB pendrives with screens.

- Public dashboards: They can also be used to reduce the consumption of electronic panels or screens that display information in airports, train stations, highway panels, signs, etc.

- Others: We also have other possible uses, such as electronic labels with e-Ink screen, smart clothing, keyboards like Dvorak's, games, etc.

E-paper display technologies

- Parties

- e-Ink B/W

- RGB color e-Ink

Regarding existing technologies, we can differentiate between several, both at a fundamental level and also in versions of the e-Ink Corporation:

Panel types

Between the types of technologies that have been developed over time to implement e-Ink screens, we have to highlight:

- Gyricon: Electronic paper was first developed in the 1970s by Nick Sheridon at Xerox's Palo Alto Research Center. The first electronic paper, called Gyricon, consisted of polyethylene spheres between 75 and 106 micrometers. Each sphere is a Janus particle composed of negatively charged black plastic on one side and positively charged white plastic on the other. The spheres are embedded in a sheet of transparent silicone, with each sphere suspended in an oil bubble so it can rotate freely. The polarity of the voltage applied to each pair of electrodes determines whether the white or black side is facing up, thus giving the pixel a white or black appearance. In 2007, Estonian company Visitret Displays was developing this type of display using polyvinylidene fluoride (PVDF) as a material for the spheres, dramatically improving video speed and lowering the control voltage needed.

- EPD (Electrospheric Display): An electrophoretic display forms images by rearranging charged pigment particles with an applied electric field. In the simplest implementation of an EPD, titanium dioxide particles about one micrometer in diameter are dispersed in a hydrocarbon oil. A dark-colored dye is also added to the oil, along with surfactants and charging agents that cause the particles to gain an electrical charge. This mixture is placed between two parallel conductive plates separated by a space of 10 to 100 micrometers. When a voltage is applied across the two plates, the particles migrate electrophoretically to the plate that carries the opposite charge to that of the particles. When the particles are located on the front (viewing) side of the screen, white appears, because light is scattered back to the viewer by the high-index titanium particles. When the particles are located on the back side of the screen, it appears dark, because the light is absorbed by the color tint. If the rear electrode is divided into a series of small image elements (pixels), then an image can be formed by applying the appropriate voltage to each region of the screen to create a pattern of reflective and absorbing regions. EPDs are typically addressed using MOSFET-based thin film transistor (TFT) technology.

- Microencapsulated electrophoretic: In the 1990s, a team of MIT undergraduate students conceived and prototyped a new type of electronic ink based on a microencapsulated electrophoretic display, originating from E-Ink Corp and used by the European Philips. This technology uses microcapsules filled with electrically charged white particles suspended in a colored oil. The underlying circuitry controls whether the white particles are at the top of the capsule (so it looks white to the viewer) or at the bottom of the capsule (so the viewer sees the color of the oil). This technology allowed the screen to be made of flexible plastic sheets instead of glass. A more recent implementation of this concept requires only a layer of electrodes beneath the microcapsules.

- Electrowetting Display (EWD): is a technology that controls the shape of a confined water/oil interface through an applied voltage. Without voltage, the (colored) oil forms a flat film between water and a hydrophobic insulating coating of an electrode, resulting in a colored pixel. By applying a voltage between the electrode and the water, the interfacial tension between the water and the coating changes, causing the water to displace the oil, creating a partially transparent or white pixel if there is a white reflective surface beneath the switchable element. Electrowetting-based displays offer several attractive features. Switching between white and colored reflection is fast enough to display video content. It is a low-power, low-voltage technology, and displays based on the effect can be flat and thin. Reflectivity and contrast are better than or equal to other types of reflective displays and approach the visual qualities of paper. Additionally, the technology offers a unique path to high-brightness, full-color displays, leading to displays that are four times brighter than reflective LCDs and two times brighter than other emerging technologies. Instead of using red, green and blue (RGB) filters or alternating segments of the three primary colors, which effectively result in only one-third of the display reflecting light in the desired color, electrowetting allows for a system in which a sub -pixel can change two different colors independently. This results in two-thirds of the display area being available to reflect light in any desired color. This is achieved by constructing a pixel with a stack of two independently controllable colored oil films plus a color filter. The colors are cyan, magenta and yellow (RGB), which is a subtractive system, comparable to the principle used in inkjet printing. Compared to LCD, brightness is gained because polarizers are not required.

- Electrofluidics: is a variant of the EWD display that places a dispersion of aqueous pigment inside a small reservoir. This deposit comprises less than 5-10% of the visible pixel area and therefore the pigment is substantially hidden from view. Voltage is used to electromechanically extract the pigment from the reservoir and spread it as a film directly behind the display substrate. As a result, the display acquires a color and brightness similar to conventional pigments printed on paper. When the voltage is removed, the surface tension of the liquid causes the pigment dispersion to rapidly retract into the reservoir. The technology can potentially provide more than 85% white state reflectance for e-paper. The core technology was invented at the University of Cincinnati's Novel Devices Laboratory and there are working prototypes developed in collaboration with Sun Chemical, Polymer Vision and Gamma Dynamics. It has a wide margin in critical aspects such as brightness, color saturation and response time. Because the optically active layer can be less than 15 micrometers thick, there is strong potential for rollable displays.

- Interferometric modulator (Mirasol): Interferometric modulator is a technology used in electronic visual displays that can create various colors through the interference of reflected light. Color is selected with an electrically switched light modulator comprising a microscopic cavity that is turned on and off using control ICs similar to those used to drive an LCD.

- Electronic-plasmonic display: is a technology that uses plasmonic nanostructures with conductive polymers. This technology features wide-range colors, high polarization-independent reflection (>50%), strong contrast (>30%), fast response time (hundreds of ms), and long-term stability. Additionally, it has ultra-low power consumption (<0.5 mW/cm2) and potential for high resolution (>10000 dpi). Since the ultrathin metasurfaces are flexible and the polymer is soft, the entire system can bend. Desired future improvements for this technology include bistability, cheaper materials, and implementation with TFT matrices. And, to do this, it is made up of two key elements or parts:

- The first is a highly reflective metasurface made of metal-insulator-metal films tens of nanometers thick that include nanometer-scale holes. These metasurfaces can reflect different colors depending on the thickness of the insulator. The standard RGB color scheme can be used as pixels for full-color displays.

- The second part is a polymer with optical absorption controllable by an electrochemical potential. After growing the polymer on the plasmonic metasurfaces, the reflection of the metasurfaces can be modulated by the applied voltage.

- reflective LCD: It is a technology similar to conventional LCD, but the backlight panel is replaced by a reflective surface.

There are other technologies developed or in development, although the above are the most important. For example, researchers are making great efforts to use organic transistors embedded in flexible substrates, simplify color displays using optics, etc.

e-Ink versions

I always advise opting for e-readers with e-Ink screens instead of LCD screens. The reason is that e-ink is not only less tiring on your eyes, but also gives you a reading experience similar to that of real paper, in addition to consuming much less energy than traditional screens. When selecting the e-Ink or e-paper screen, you should know that there are various versions of the technologies available today patented by e-Ink Holdings, such as:

- Vizplex: This was the first generation of e-ink displays, used by some very popular brands in 2007.

- Pearl: This improvement was introduced three years later and was used by Amazon for its Kindle, as well as in other models such as Kobo, Onyx and Pocketbook.

- Mobius: It is similar to the previous ones, but includes a layer of transparent and flexible plastic on the screen to better resist shocks. Onyx, a Chinese company, was one of those that used this screen.

- triton: It was first introduced in 2010, although a second improved version was released in 2013. This technology included color for the first time in electronic ink displays, with 16 shades of gray and 4096 colors. Pocketbook was one of the first to use it.

- Letter and Letter HD: They were released in 2013, and there are two different versions. The e-Ink Carta has a resolution of 768×1024 px, 6″ in size and a pixel density of 212 ppi. As for the e-Ink Carta HD version, it increases to 1080x1440 px resolution and 300 ppi, maintaining 6 inches. This format is very popular, used by the best current e-reader models.

- Kaleido: This technology arrived in 2019, with a Plus version in 2021 and a Kaleido 3 version in 2022. They are improvements to the color screen, based on grayscale panels by adding a layer with a color filter. The Plus version improved texture and color for a clearer image, and the Kaleido 3 offers much more vivid colors, with 30% greater color saturation than the previous generation, 16 levels of grayscale and 4096 colors.

- Gallery 3: It is the most recent model, and just arrived in 2023, it is based on ACeP (Advanced Color ePaper) to achieve more complete colors and with a single layer of electrophoretic fluid controlled by voltages compatible with commercial TFT backplanes. It is a color e-Ink technology that improves response time, that is, the time it takes to change from one color to another. For example, from white to black in just 350 ms, and between colors, depending on the quality it can go from 500 ms to 1500 ms. In addition, they come with a ComfortGaze front light that reduces the amount of blue light reflected on the surface of the screen so that you can fall asleep better and do not cause so much eye strain.

Future

Plastic Logic Germany is a company (developer + factory) that originated as a spin-off project of the Cavendish Laboratory at the University of Cambridge. It was founded in 2000 by Richard Friend, Henning Sirringhaus and Stuart Evans. The company specializes in the development and manufacturing of electrophoretic screens (EPD), based on organic thin film transistor (OTFT) technology, in Dresden, Germany. Thanks to them, information could be represented as on a conventional screen, but on a flexible panel. Making great contributions to the field of current flexible screens, and it seems that they will be the future as we are seeing in many cases. Combining this technology with ePaper or e-Ink will result in elements very similar in weight and flexibility to sheets of paper, with all their applications and advantages...